Bambu Lab AMS - Innovation of 3D printing technology

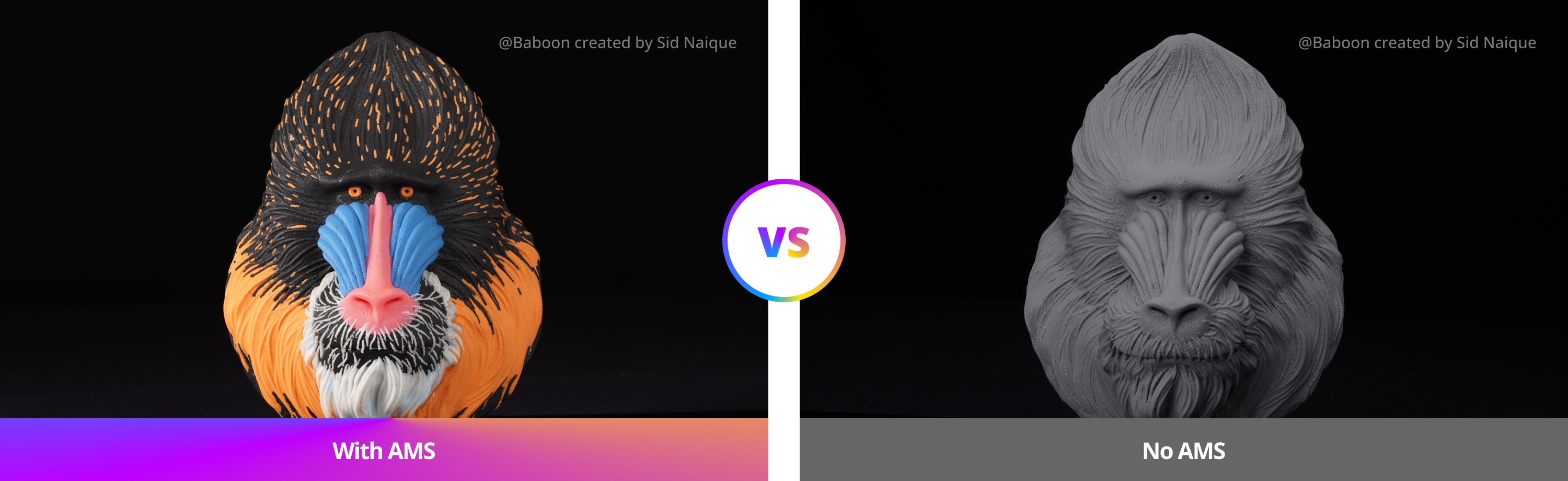

Make Multi-Color 3D Printing Real

Color, the ultimate expression of emotions, is brought to you by Bambu Lab's Automatic Material System (AMS). You can now enjoy printing freely in multiple colors and materials.

Multi-Material Printing

Applicable to most materials such as PLA, ABS, ASA, PETG, PC, etc.

Hassle-Free Support Removal

With AMS, Bambu Lab printers can use snap-away support material or dissolvable filament to minimize the pain of removing supports.

No More Filament Leftover

Without AMS, when the filament runs out, manual spool replacement interrupts printing and results in wasted filaments.

With AMS, there is a seamless transition to a new spool which keeps uninterrupted printing and minimizes waste.

Filament Backup

Your print never stops with automatic spool changing. With AMS filament backup function, never worry about running out of filament during your sleep or absence, ensuring a seamless and uninterrupted printing process, preventing any filament waste and promoting energy efficiency.

Advanced Intelligent System

Powered by a 32-bit MCU, sensor arrays, actuators, and a smart algorithm, the AMS has reached unprecedented levels of intelligence. It expertly manages filament loading and unloading, along with efficient fault detection and recovery.

For more detailed information please refer to AMS feeding system.

Filament Tangle Detection

When the filament at the toolhead encounters resistance, it may be that the filament is tangled or the spool is stuck, AMS can detect it immediately and suspend printing to avoid air printing.

For more detailed information please refer to filament entangled.

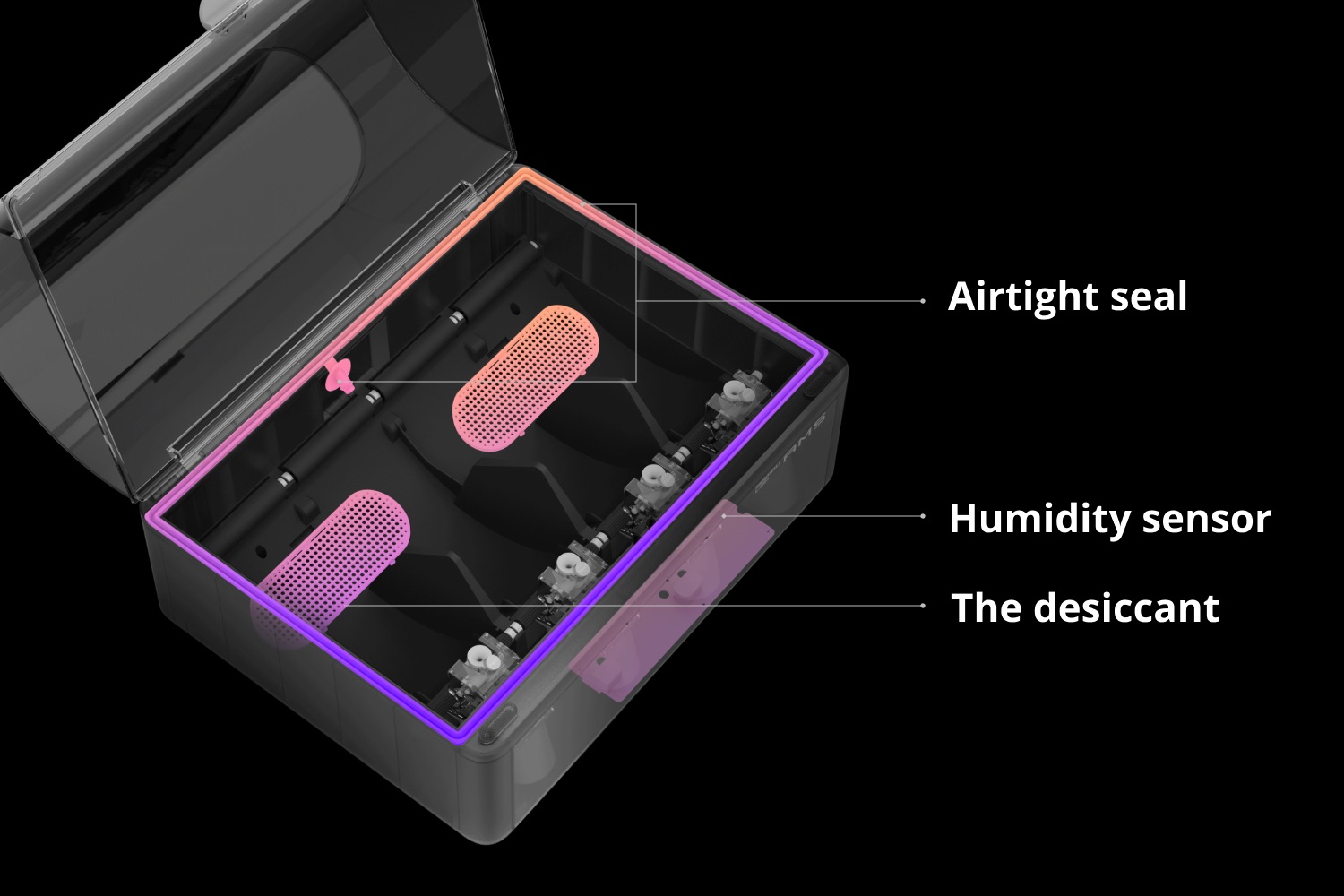

Say Goodbye to Wet Filaments

Filament that has absorbed moisture can lead to print quality issues and poor layer adhesion, or even nozzle clogging that can lead to a failed print.

Keep the Filament Dry

The AMS has an air-tight seal and with the help of dessicant material, it absorbs moisture to keep the moisture away from Filament.

A Humidity Sensor a

lso detects the humidity inside the AMS and provides information to the user when the humidity is higher or the dessicant may need to be replaced.

For best print quality, dry filament is required.

Automatic Filament Identification

Bambu Lab filaments use RFID which is read by the AMS to automatically identify and apply the best settings for your material.

The RFID tag is synchronized automatically to Bambu Studio.

Non Bambu Lab Filaments need to be manually configured in Bambu Studio or in the printer.

Support Up to 16 Colors

Each Bambu Lab AMS is composed of 4 filament slots, and up to 4 AMS can be installed in parallel and supports up to 16 colors for stunning prints that truly stand out. To achieve 16-color printing, connect 4 AMS via AMS hub

Overview:

- Bambu Lab AMS is an intelligent system that communicates with the toolhead to guarantee smooth feeding and automatic mid-print filament switching. It can detect the tension on filament and actively adjust the feeding pace. With RFID technology, Bambu Lab AMS identifies filament loaded inside and automatically configures the most appropriate print settings.

- Bambu Lab AMS equipped with humidity sensors and with an airtight enclosure, it keeps the filament dry and ready to use, which is especially helpful for engineering grade materials such as nylon and polycarbonate, which are hydroscopic.

- Each Bambu Lab AMS is composed of 4 filament slots, and up to 4 AMS can be installed in parallel. With multiple filament slots at disposal, it's now possible to use snap-away support material or dissolvable filament to minimize the pain of removing supports

- Each AMS unit comes with 4 Reusable Spools (1 high temperature spool and 3 low temperature spools).