Bambu Support for ABS

Enhance your ABS printing experience with our innovative support material. Designed for effortless printing and hassle-free removal, this material ensures a flawless support interface every time. Fully compatible with the AMS systems, it streamlines your ABS printing process from start to finish. Say goodbye to tedious support removal and enjoy a smoother, more efficient workflow!

Easy Support Removal

Specially formulated for ABS, our support material adheres precisely to the ABS surface, allowing for easy support removal. This streamlines your post-processing work, ensuring a more efficient workflow.

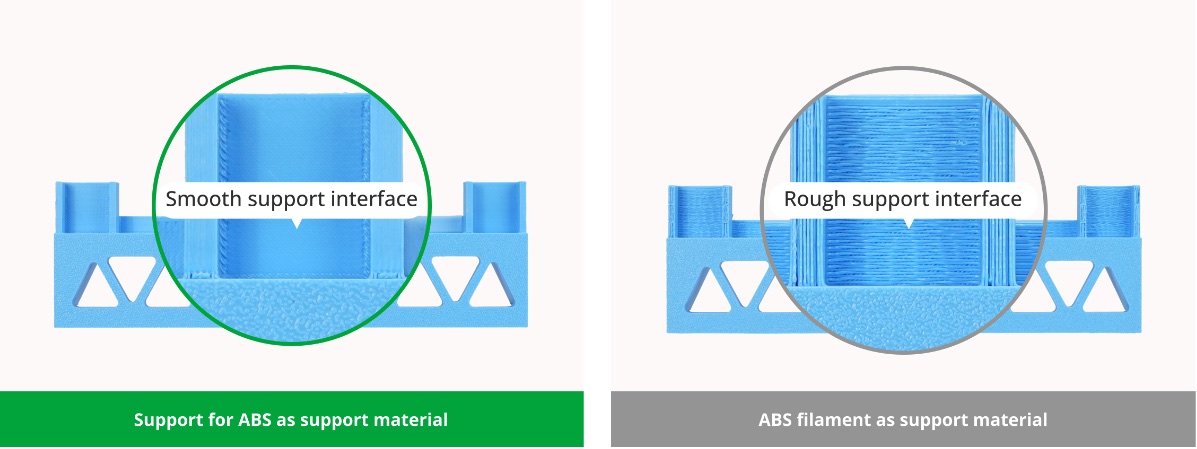

Superior Support Interface Quality

Support for ABS enables a 0 Top Z distance and 0 Top interface spacing when printing, ensuring a scar free support surface. This enhances the sharpness of details, improving the overall appearance and integrity of your final prints.

Accessory Compatibility

Learn more different filaments comparison on Bambu Filament Guide >>

Printing Tips

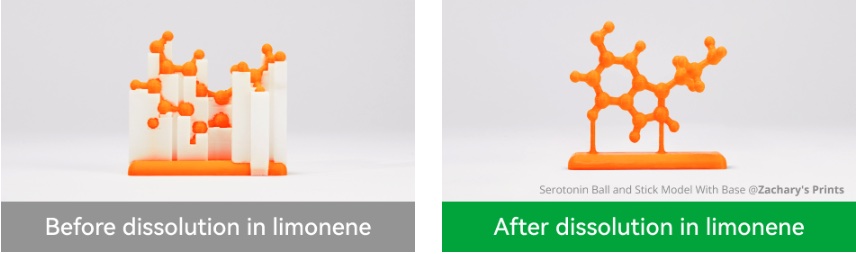

• Support for ABS is soluble in limonene. Please pay attention to the usage norms and safety.

• Pungent and unpleasant odors may be released during printing. Make sure your printer is enclosed and placed in a well-ventilated area.

• When layer strength is required, it is recommended to increase the flushing volume to above 800 mm³. If the flushing is not thorough, it may reduce the layer adhesion of the model at surfaces that are on the same horizontal plane as the support surface.

• By increasing the "initial layer speed", a more peelable support can be obtained. However, this will increase the risk of warping.

• Dry out before use for higher print quality. Drying conditions: 80℃ for 4 hrs in the blast drying oven; 85 - 95 ℃ for 6 hrs in the X1 Series Heatbed. Please refer to Filament drying instructions on WIKI.

• For more support-related settings, please refer to Support on WIKI.

Downloads

Filament TDS

Filament TDS

Filament MSDS

Filament MSDS

Filament RoHS

Filament RoHS