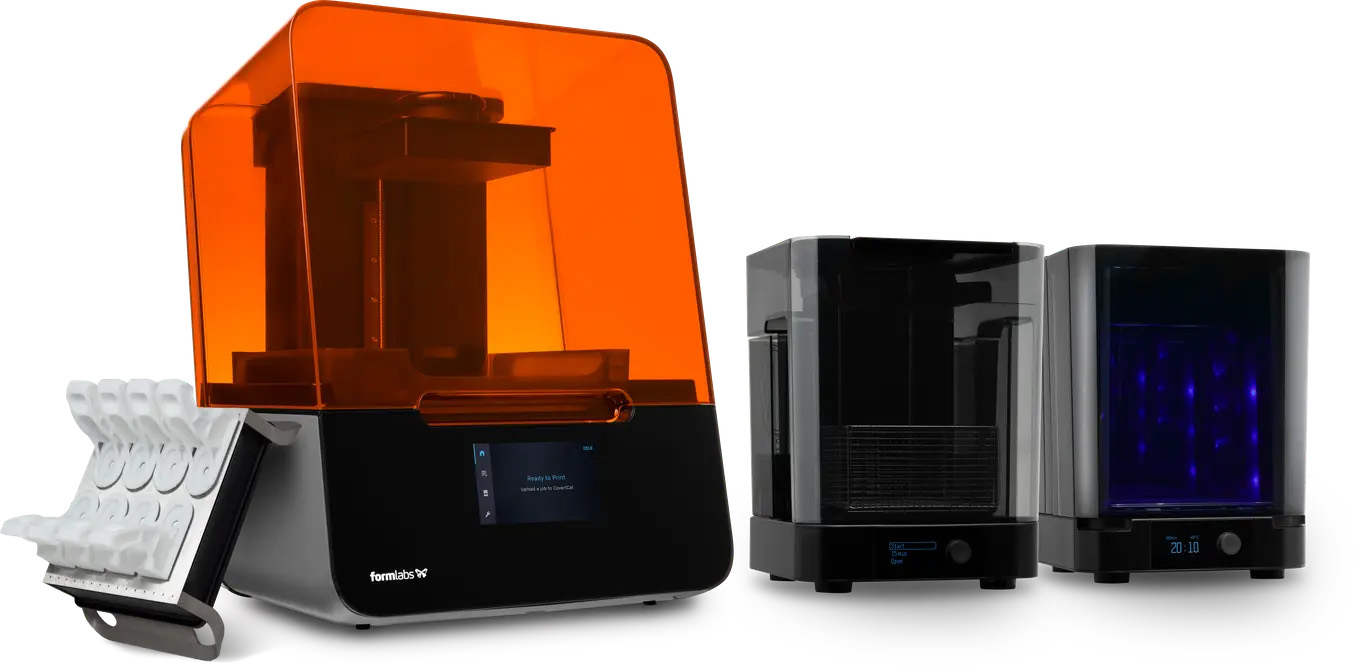

Product Description

Form Wash revolutionizes the 3D print washing process, ensuring consistency, thorough cleaning, and a mess-free experience. Whether you're transferring parts directly from your 3D printer or need to rinse them on the build platform or in a wash basket, Form Wash has you covered.

Designed to cater to parts printed on our Form 3 generation printers, Form Wash also accommodates smaller components produced with our large-format 3D printers, Form 3L, and Form 3BL.

With Form Wash, you can streamline your 3D printing process, reduce the time and effort required, and produce high-quality, pristine parts consistently. Say goodbye to the complexities of manual washing, and embrace the future of automated, efficient, and reliable part cleaning.

Here are some of the key features that make Form Wash a game-changer for your 3D printing workflow:

Features

- Quick and Effortless Setup

Transition your printed parts from the printer to Form Wash, either by keeping them on the Build Platform or by placing them in the wash basket. The setup process is straightforward, saving you time and effort.

- Compatibility with All Formlabs Materials

Simply select your preferred material from the list, and Form Wash will automatically determine the appropriate cleaning time. This ensures that your parts are cleaned effectively and without any manual adjustments.

Form Wash employs an impeller to precisely agitate your parts in isopropyl alcohol (IPA), reaching even the most intricate nooks and crannies. The result is a perfectly cleaned and ready-to-use component.

Forget about the hassles of manual washing, which can sometimes lead to warping if parts are left in IPA for too long. Form Wash takes care of this with an automated process. Once the washing cycle is complete, it lifts your parts out of IPA, allowing them to air dry effortlessly.

What's Included

Post-Processing Tech Specs

| FORM WASH | FORM WASH L | | |

|---|

| Printer Compatibility | Form 3, Form 3B, Form 2 | Form 3L, Form 3BL, Form 3, Form 3B, Form 2 | | |

|---|

| Dimensions | 26.2 x 29.3 x 34.0 cm

10.3 x 11.5 x 13.4 in

Height when open: 64 cm (25.2 in) | 78.0 x 46.0 x 67.0 cm

30.7 x 18.1 x 26.4 in

Height when open: 113 cm (44.5 in) | | |

|---|

| Weight | 6.7 kg

14.5 lbs | 56.7 kg (without solvent)

125lbs (without solvent) | | |

|---|

| Bucket Volume | 8.6 L | 37.9 L

10 US gal | | |

|---|

| Maximum Part Size | 14.5 × 14.5 × 17.5 cm

5.7 x 5.7 x 6.9 in | 33.5 x 20 x 30 cm

13.2 x 7.9 x 11.8 in | | |

|---|

| Suggested Operating Environment | Suggested 18—28 °C

Suggested 64—82 °F | Suggested 18—28 °C

Suggested 64—82 °F | | |

|---|

| Agitation Method | Magnetically coupled impeller | Magnetically coupled impeller | | |

|---|

| Included Accessories | a. Wash Bucket

b. Wash Basket

c. Hydrometer

d. Siphon Pump

e. Flexible Scraper

f. Scraper

g. Tweezers

h. Flush Cutters | a. Wash Bucket

b. Wash Basket

c. Electric Solvent Pump

d. Flexible Scraper

e. Scraper

f. Flush Cutters

g. Rinse Bottle

h. Gloves

i. Form 3 Build Platform Adaptor | | |

|---|

| Power Requirements | 90–240 V

2.0 A 50/60 Hz

50 W | Input (NA) 100 - 120 VAC, 50-60Hz, 1A

Input (EU) 220 - 240 VAC, 50-60Hz, 1A | | |

|---|

| Compatible Solvents | IPA, TPM, Water | IPA, TPM, Water

|

|---|