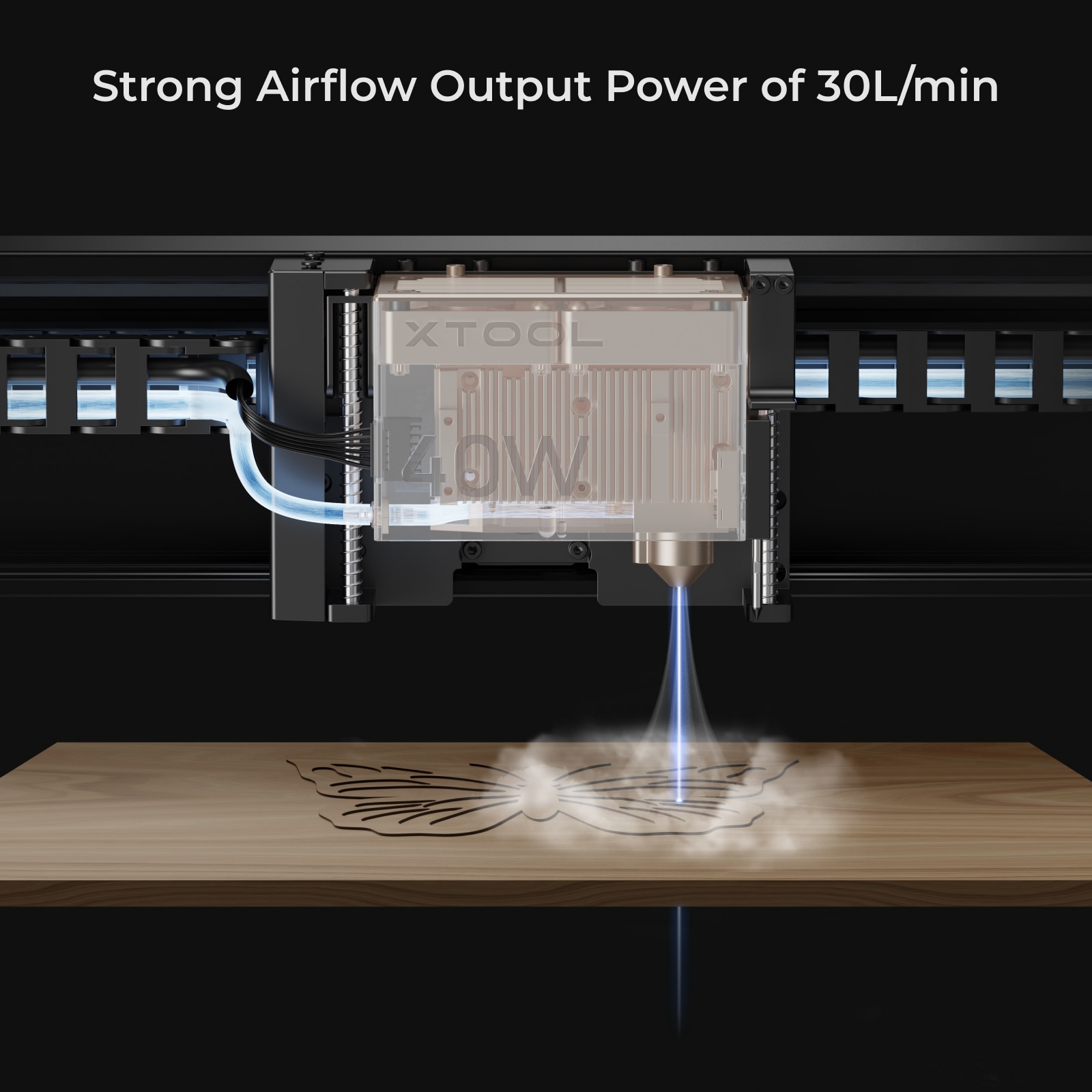

Improved Quality

During laser cutting, the material undergoes burning to achieve engraving or cutting. This action can leave behind unwanted deposits on the surface, which affects the final appearance. The air assist laser cutting technique blows away these particles as they form. This results in fine, smooth, and quality cuts.

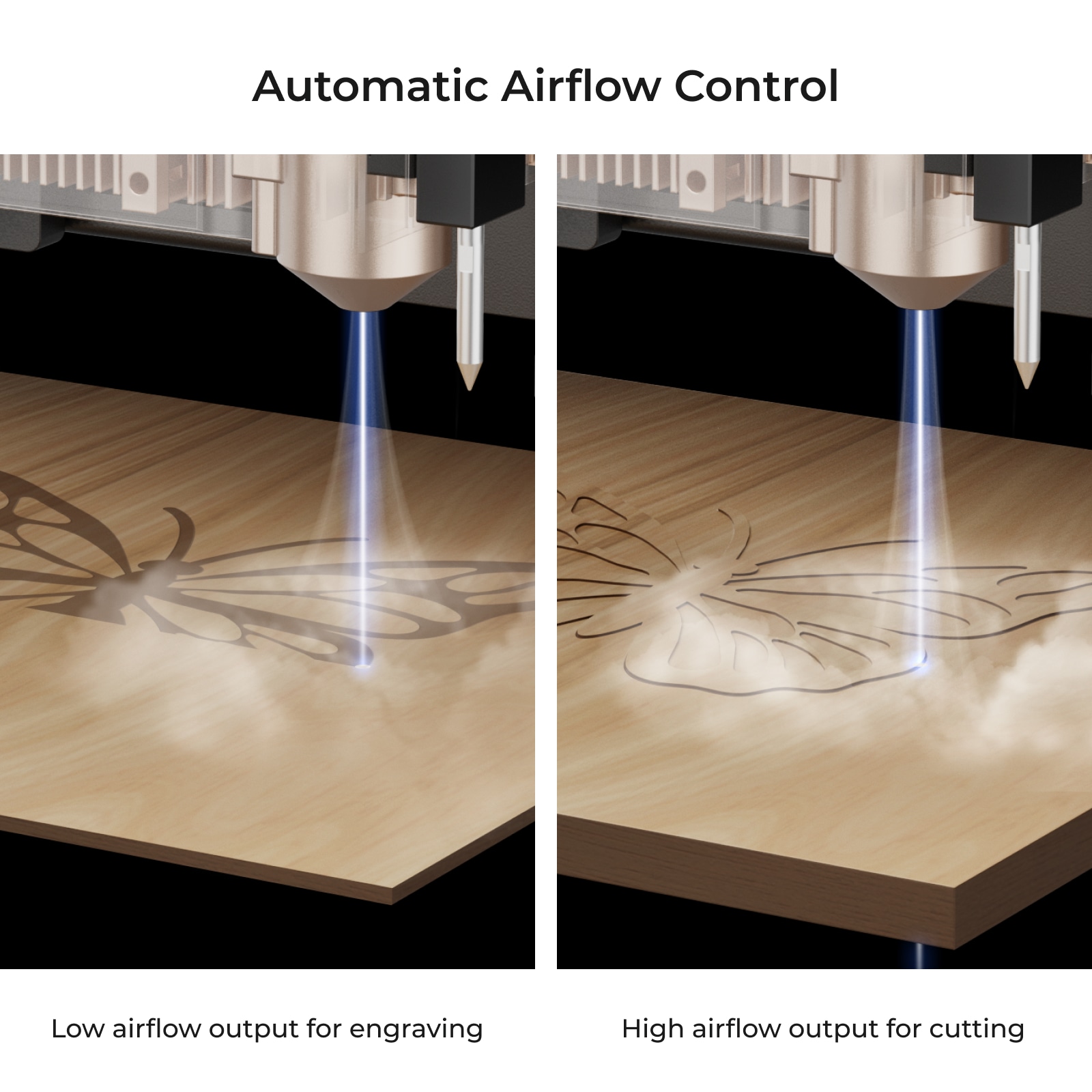

Safeguards the Laser Lens

The air assist mechanism efficiently clears away the smoke and debris produced during the laser’s operation. This action keeps the laser head lens free from contaminants and enhances its longevity.

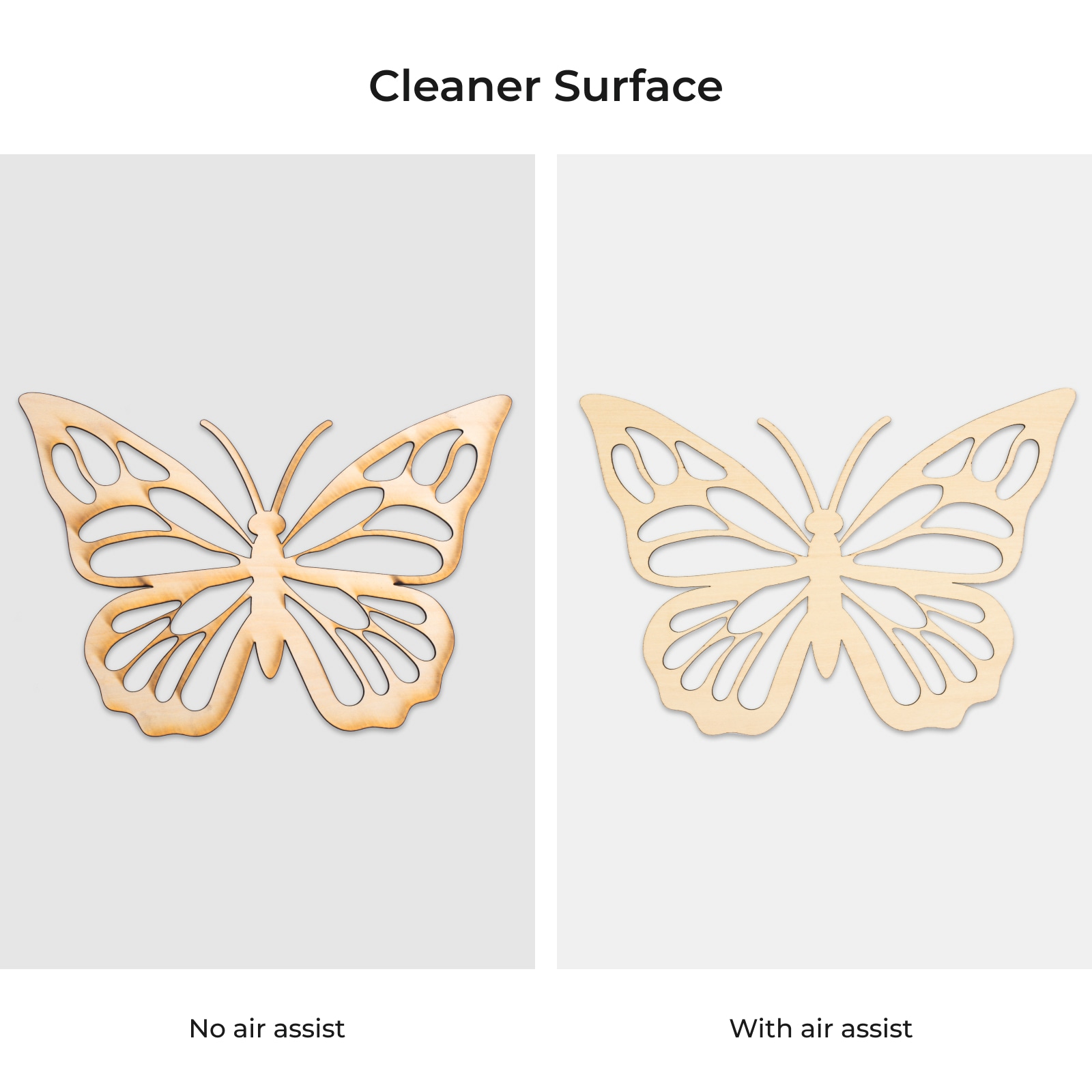

Reduce Charring

Laser operations on wood often result in burnt marks around the cut. This blackened, partially burnt region is termed ‘char’. However, when a stream of compressed is thrown along with the laser, it prevents the laser from burning those adjacent areas, reducing charring.

Pristine Finish

The compressed air rapidly cools the surface being cut, preventing any warping or color changes caused by excessive heat. This ensures the end product has crisp lines, detailed patterns, and a flawless surface.