RFID for Intelligent Printing

All printing parameters are embedded in RFID, which can be read through our AMS (Automatic Material System).

Load and print! No more tedious setting steps.

Downloads

Filament TDS

Filament TDS

Filament MSDS

Filament MSDS

Filament RoHS

Filament RoHS

Printing Tips

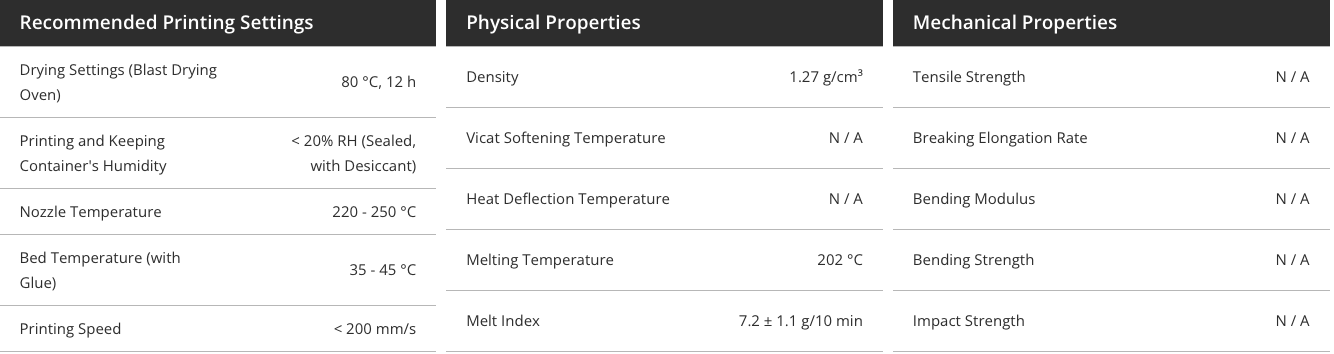

• Drying conditions: 80 °C for 12 hrs. To achieve optimal printing performance, it is recommended further drying before use and after storage. For more details please refer to: Filament drying instructions on WIKI.

• Please carefully read PVA Printing Guide before starting the printing process.

• PVA is suitable for use with AMS and AMS lite in a dry state. If the filament becomes soft or sticky due to moisture, it must be dried again before use to prevent issues such as feeding failure, nozzle clogging, and low print quality.

• PVA may darken in color after extended storage or multiple drying cycles, but it won't affect its printing performance or support capabilities.

• Recommend to use normal support instead of tree support. Tree support is more likely to collapse during printing.

• Use warm water to speed up the dissolving process. But if supporting PLA, the maximum water soaking temperature should not exceed 50°C to prevent deformation of the main model.

• Waiting for complete dissolution is not necessary when soaking and dissolving PVA support. You can manually remove the partially dissolved PVA support to reduce the waiting time.

• When dissolving supports in water, some parts of the main model may leak in water. To mitigate this risk, please refer to: Reduce the risk of prints leakage guide on WIKI.

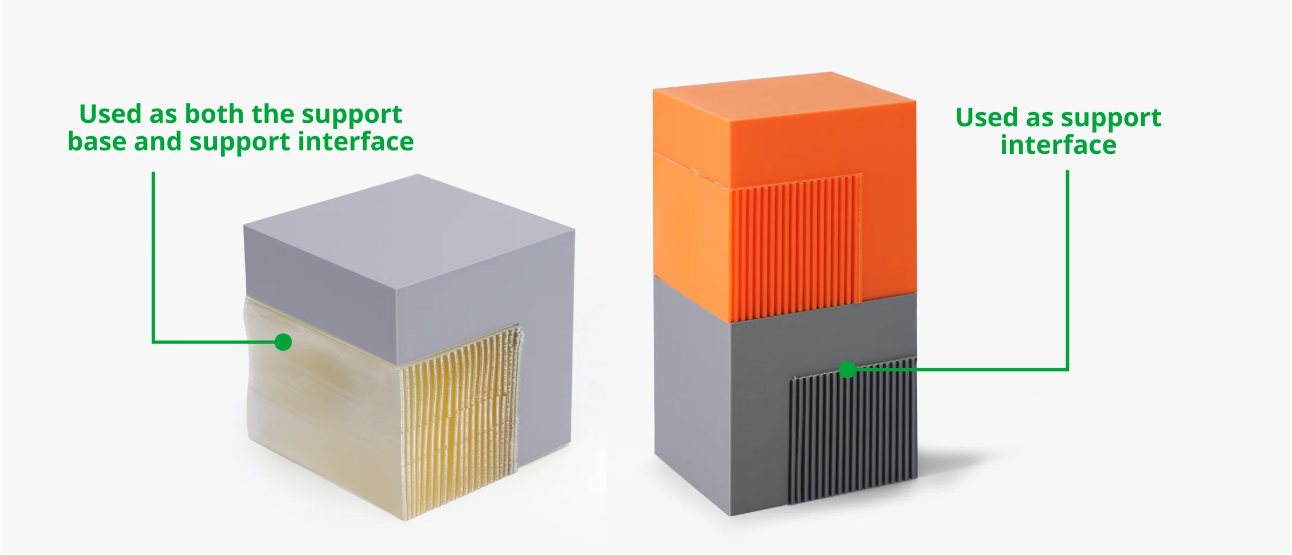

• Depending on the use case, Bambu PVA can also be used solely for printing the support interface to minimise material waste and printing time.