PolyTerraTM PLA is a bioplastic based 3D printing filament designed from the ground up to create the next generation of PLA, providing ease of use, printing quality, speed and reliability. It is a sustainable product sourced naturally and for every spool produced a tree is planted to give back to the earth.

Key Features

- Matte Surface & Fun Colours - Print parts with a beautiful matte surface finish and unleash your imagination with PolyTerra™ PLA's fun and vibrant colour range. PolyTerra™ PLA renders models with an excellent matte surface quality and features good overhang and bridging capability.

- Optimized for Support - PolyTerra™ PLA has been engineered with excellent support removal properties, enabling users to more easily break away support or rafts from the surface of their prints.

- Easy Sanding - PolyTerra™ PLA is softer and easier to sand in comparison to regular PLA filaments and can be easily painted.

- Bioplastic PLA Formula - PolyTerra™ PLA is a newly developed material from Polymaker called FBC (Fully Bio Compound). It is a compound of high quality Ingeo PLA and compounded with naturally occurring elements. PLA is biodegradable under industrial composting conditions however the degradation rate is very slow in ambient temperatures. Polymakers FBC formula contains less PLA plastic to degrade making PolyTerra™ PLA a more environmental friendly material.

- Eco-sustainable Packaging & Carbon Offset – Polymaker are committed to helping combat plastic waste, as such PolyTerra™ PLA comes on a fully recycled cardboard spool with recycled labels and box. Furthermore, Polymaker will plant one tree in Australia through the ONETREEPLANTED association for every locally sold spool of PolyTerra™ PLA.

- Improved Ductility - PolyTerra™ PLA delivers improved ductility which is less brittle (Charpy Impact) in X-Y axis than standard PLA formulations.

- Compatibility / Jam-Free™- PolyTerra™ PLA is compatible with a wide range of 3D printers and is manufactured with Polymakers Jam-Free™ technology which leads to excellent printing quality with zero risk of nozzle jams caused by heat creep [1]. PolyTerra™ PLA works well on most printing surface with a thin layer of glue stick applied, no heated bed is required but can sometimes be used at 40 - 50°C for better results (maximum 60°C).

- Uncompromised Quality - PolyTerra™ PLA filament is made with the highest quality ingredients including Ingeo® from Natureworks; a high quality PLA material produced from rapidly renewable plant resources in the US. Combining Polymakers innovative R&D technologies, compounding and extrusion systems with Natureworks Ingeo® resins produces a reliable 3D printing filament to print beautiful and accurate models.

[1] Heat creep is the the process of heat spreading irregularly throughout the hot end, one common example is with all metal hot end designs. Once heat creeps towards the cold end, the PLA filament softens prematurely in the cold end and expands resulting in a jam. Polymakers Jam-Free™ technology increases the heat resistance of the filament itself (not the printed part) to 100˚C which prevents the filament from prematurely softening in the cold end and can still melt rapidly once entering the heating zone.

Carbon Foootprint

High quality raw ingredients are critical to manufacturing consistent and reliable filament, for this reason Polymaker partnered with NatureWorks and use Ingeo PLA resins as a core ingredient for their range of PLA filaments. Polymakers innovative R&D technologies, compounding and extrusion systems combined with Natureworks Ingeo resins produce a reliable 3D printing filament.

Abundant and rapidly renewable plant resources capture and sequester atmospheric carbon over their growing season, producing simple sugars via the process of photosynthesis. Through a process of fermentation and separation, these harvested plant sugars are converted into lactic acid. A lactic acid building block is transformed into Ingeo, a performance thermoplastic with physical characteristics and performance tailored for filament production and printing.

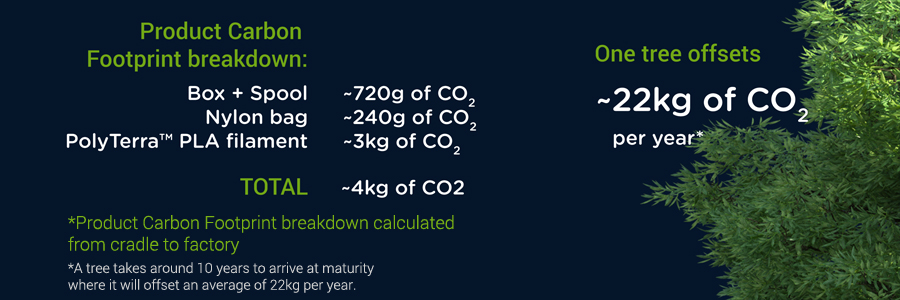

PolyTerraTM PLA is a naturally sourced product and for every spool sold Polymaker want to give back to the earth by planting one tree through the ONETREEPLANTED association. Below you can see a breakdown of PolyTerraTM PLA's Carbon Footprint.

Commercial Compostability

PolyTerraTM PLA is a newly developed material from Polymaker called Fully Bio Compound (FBC) - a bioplastic mainly made with NatureWorks high quality Ingeo PLA and compounded with naturally occurring elements which reduces the plastic content of PolyTerra PLA by 15- 20%. With this new formulation, Polymaker have improved the compostability rate of PLA to drive the global effort towards composting bioplastics in commercial composting facilities*.

*Commercial composting timescales are typically 8-10 weeks for PAS 100.

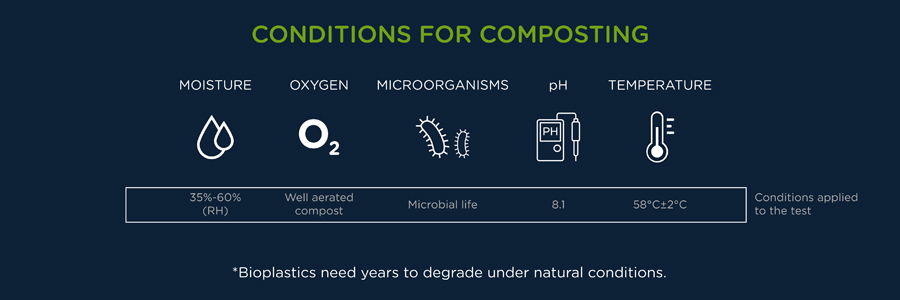

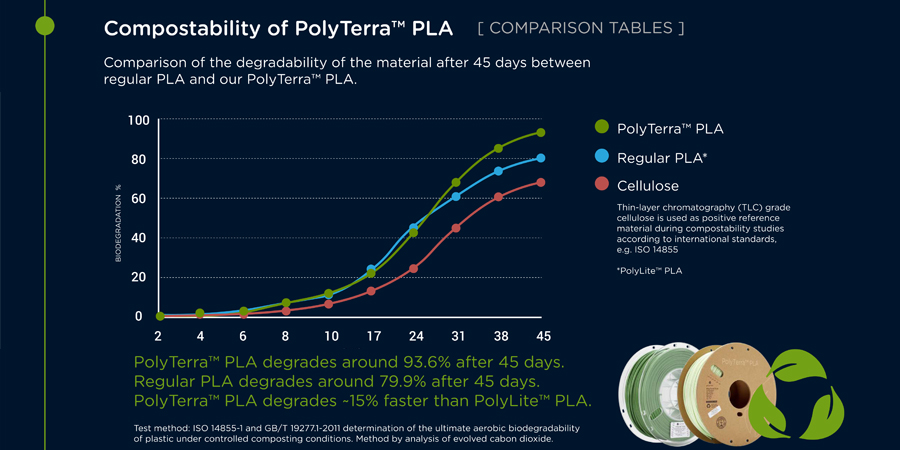

Polymaker ran a compostability test, certified to ISO 14855-1, with a third party laboratory that revealed thanks to the organic compounds, PolyTerraTM PLA degraded faster than a comparable PLA material. The test was completed by putting small pellets of PolyTerraTM

PLA in a 2-4 months old plant compost (including a wide variety of microorganisms)

and heating the system up to 60 ̊C. During this process the PolyTerraTM PLA will start to decompose into carbon dioxide, water and mineral salts and the aforementioned elements are monitored in order to calculate the mass of PolyTerraTM PLA degraded.

After 45 days, 93.6% of PolyTerra PLA degraded and 79.9% of PolyLite PLA degraded. The testing demonstrated that PolyTerraTM PLA degraded up 15% faster than PolyLiteTM PLA and from Polymakers estimation it could take less than 100 days for PolyTerra PLA to fully degrade.

Please note that PolyTerraTM PLA degrades under the specific conditions of industrial composting, namely, at certain temperature and humidity with the presence of micro- organisms. The degrade rate will depend on the size and thickness of the printed part. When PolyTerraTM PLA is correctly composted, it breaks down into carbon dioxide, water, biomass and mineral salts of any other elements present. The material fully degrades with no toxic residues and the compost supports plant growth.