Bambu TPU for AMS

Bambu TPU for AMS redefines your TPU printing experience with enhanced performance and seamless AMS integration. Perfectly suited for vibrant multicolor projects, it opens up exciting possibilities in flexible material printing. With a Shore hardness of 68D, Bambu TPU for AMS offers impressive toughness while minimizing stringing, delivering the ease of PLA printing alongside TPU's signature flexibility and durability.

Seamless AMS & AMS lite Integration

Optimized for use with the AMS system, Bambu TPU for AMS enables smooth and reliable multicolor printing with flexible materials.

Tough Yet Flexible

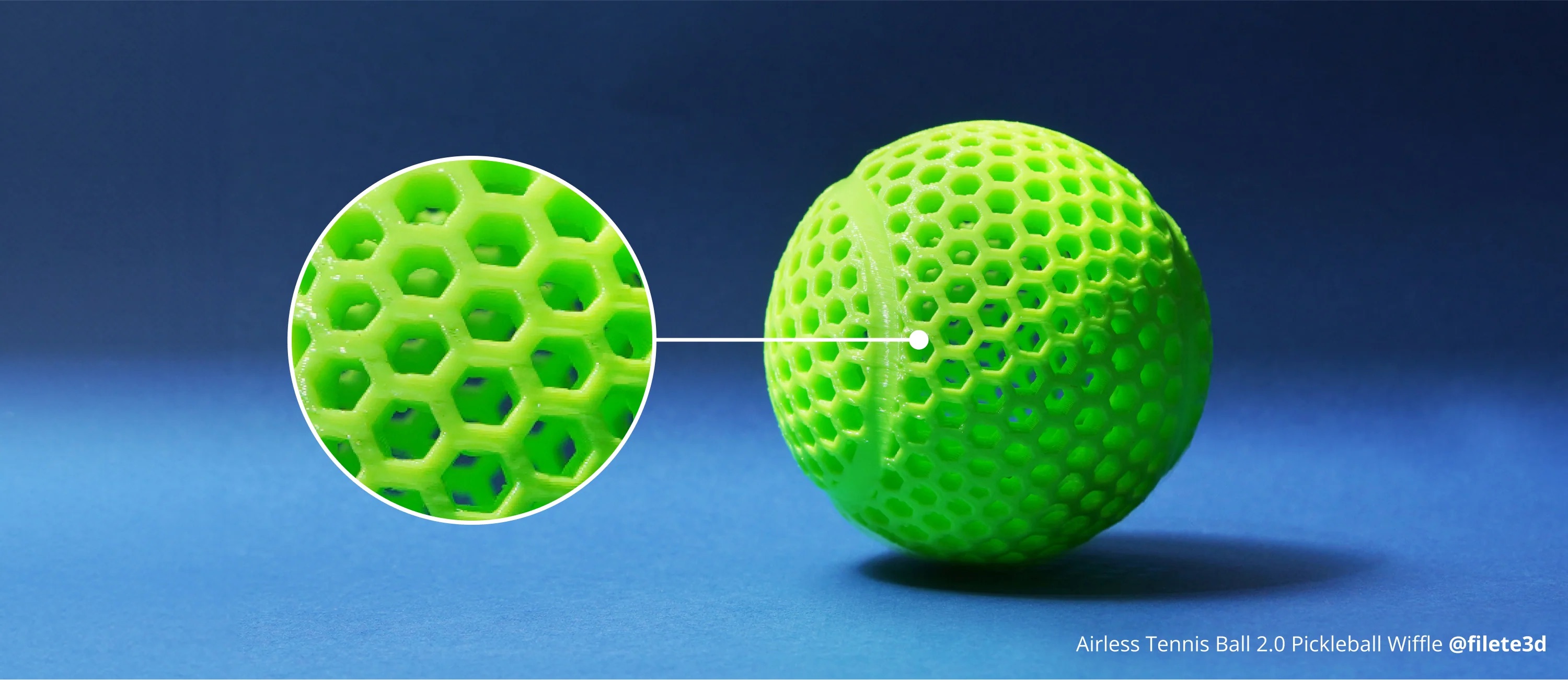

With a Shore hardness of 68D, Bambu TPU for AMS combines exceptional toughness with the flexibility and durability of TPU. It's ideal for printing durable, impact-resistant parts like protective cases, phone covers, door stoppers, sports equipment, automotive parts, and much more!

Goodbye, TPU Stringing

Say farewell to stringing with Bambu TPU for AMS! Its special formulation greatly minimizes the common stringing problems found in traditional TPU, ensuring clean, crisp details in every print for a smoother and more reliable printing experience.

Blazing Fast TPU Printing

Bambu TPU for AMS delivers up to 60% faster print speeds compared to Bambu TPU 95A HF, boosting efficiency without compromising on quality. Get more done in less time with rapid, reliable results!

| Bambu TPU for AMS | Bambu TPU 95A HF |

Nozzle Temperature (℃) | 230 | 230 |

Max Volumetric Speed (mm³/s) | 18 | 12 |

Printing Speed (mm/s) | Up to 238 | Up to 147 |

Model Specimens | Diameter: 50mm Height: 100mm Infill: 40% |

Application Tips

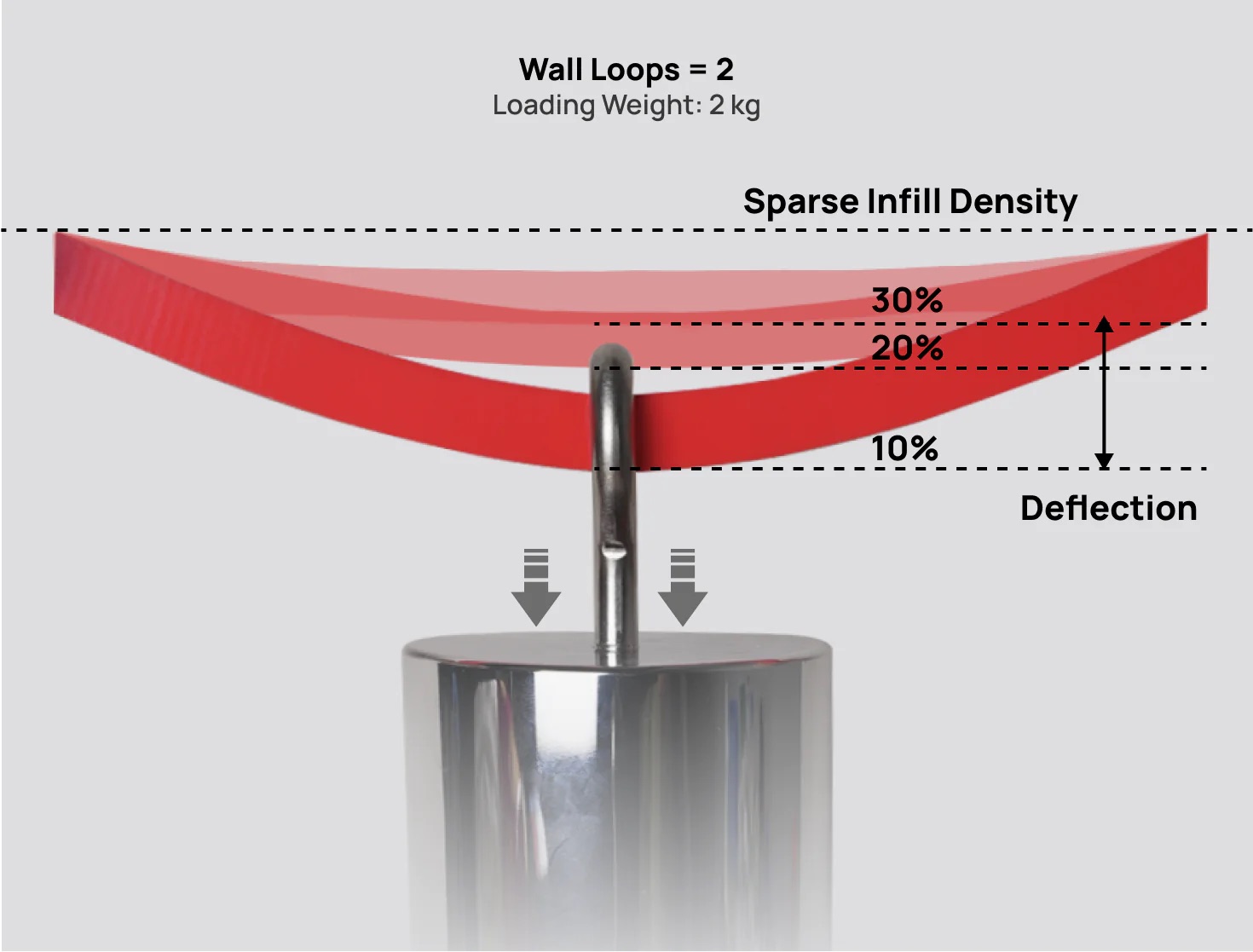

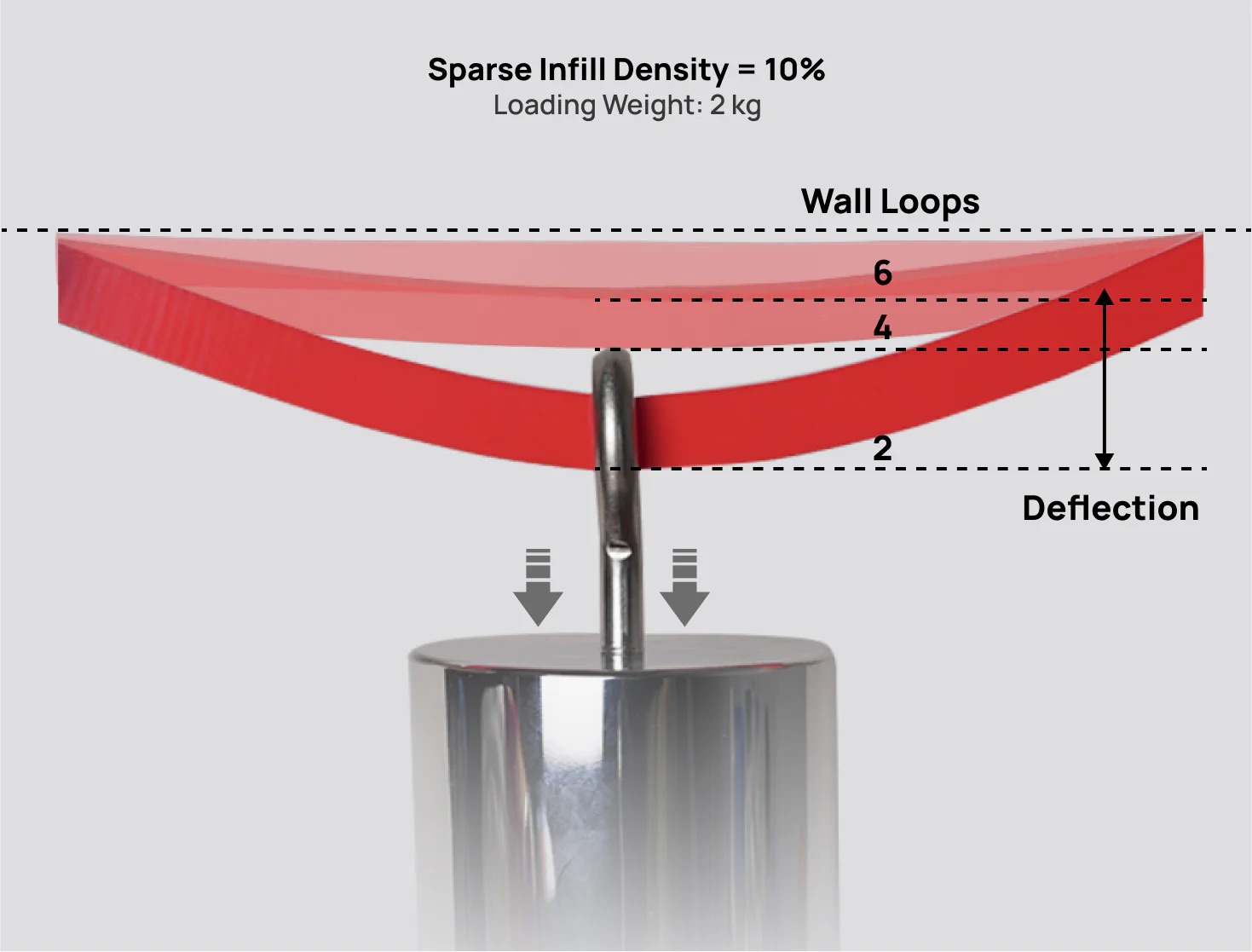

The elasticity of TPU prints is related to the Wall Loops and Sparse Infill Density setting. The higher the wall loops or sparse infill density, the lower the elasticity, and vice versa.

Accessory Compatibility

| Recommended | Not Recommended |

Build Plate | Textured PEI Plate / Smooth PEI Plate | / |

Hotend | Hardened Steel Nozzle (0.4 mm / 0.6 mm / 0.8 mm)

Stainless Steel Nozzle (0.4 mm) | Hardened Steel Nozzle (0.2 mm)

Stainless Steel Nozzle (0.2 mm) |

Glue | Bambu Liquid Glue

Glue Stick | / |

AMS & AMS lite | AMS & AMS lite | / |

TPU for AMS Hex Code Table

Color | Hex Code |

Red | #ED0000 |

Blue | #5898DD |

White | #FFFFFF |

Gray | #939393 |

Black | #000000 |

RFID for Intelligent Printing

All printing parameters are embedded in RFID, which can be read through our AMS (Automatic Material System).

Load and print! No more tedious setting steps.

Recommended Printing Settings

Drying Settings (Blast Drying Oven) | 70 °C, 8 h |

Printing and Keeping Container's Humidity | < 20% RH (Sealed, with Desiccant) |

Nozzle Temperature | 220 - 240 °C |

Bed Temperature (with Glue) | 30 - 35 °C |

Printing Speed | < 250 mm/s |

Physical Properties

Density | 1.26 g/cm³ |

Vicat Softening Temperature | N / A |

Heat Deflection Temperature | N / A |

Melting Temperature | 183 °C |

Melt Index | 21.8 ± 0.3 g/10 min |

Mechanical Properties

| Tensile Strength | 22.4 ± 0.6 MPa |

| Breaking Elongation Rate | >650 % |

| Bending Modulus | N / A |

| Bending Strength | N / A |

| Impact Strength | N / A |

Downloadable Resources

Filament MSDS

Filament MSDS

Filament RoHS

Printing Tips

• Dry before use for higher printing quality. TPU for AMS must be dried before use and kept moisture-free during the printing process to prevent stringing.

• Drying conditions: 70℃ for 8 hrs in a blast drying oven, or 80°C to 90°C for 12 hours on an X1 printer's heatbed. For more details please refer to: Filament drying instructions on WIKI.

• Storage tips: To prevent the filament from absorbing moisture, use an airtight storage container with desiccant during printing.