Bambu PA6-GF - Glass Fiber Reinforced Nylon

Bambu PA6-GF, also known as Nylon 6 with Glass Fiber, stands at the forefront of high-performance engineering plastics. Engineered to deliver exceptional strength, durability, dimensional stability. The PA6-GF is also more cost effective when compared to other top tier engineering filaments.

Built to Last

Bambu PA6-GF is exceptionally strong and durable due to reinforced glass fibers, making it the perfect choice for prints that need to withstand heavy use and resist bending or breaking.

* Note: The printed part achieves better toughness after exposure to moisture.

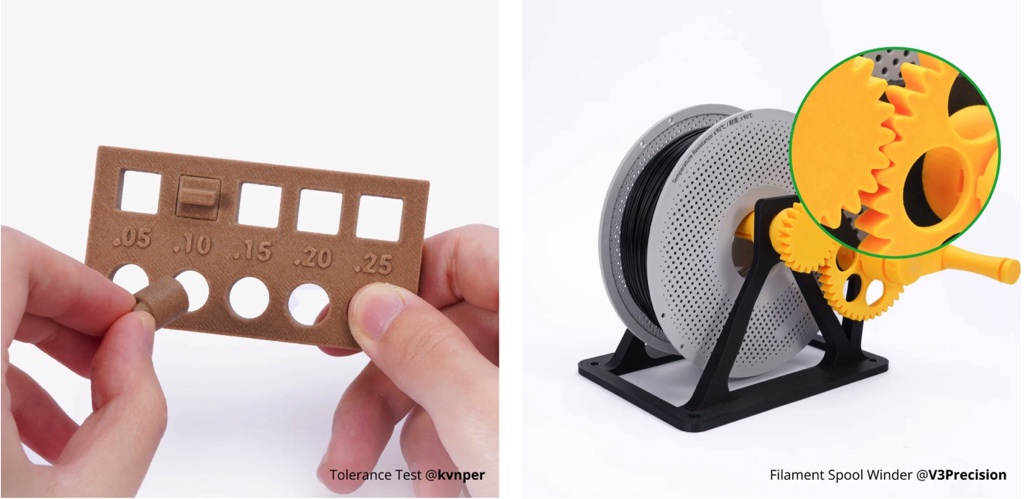

Dimensional Stability

PA6-GF boasts unparalleled dimensional stability thanks to its glass fiber reinforcement, minimizing warping in comparison to standard PA filaments. Print with precise dimensions, even in the most intricate geometries.

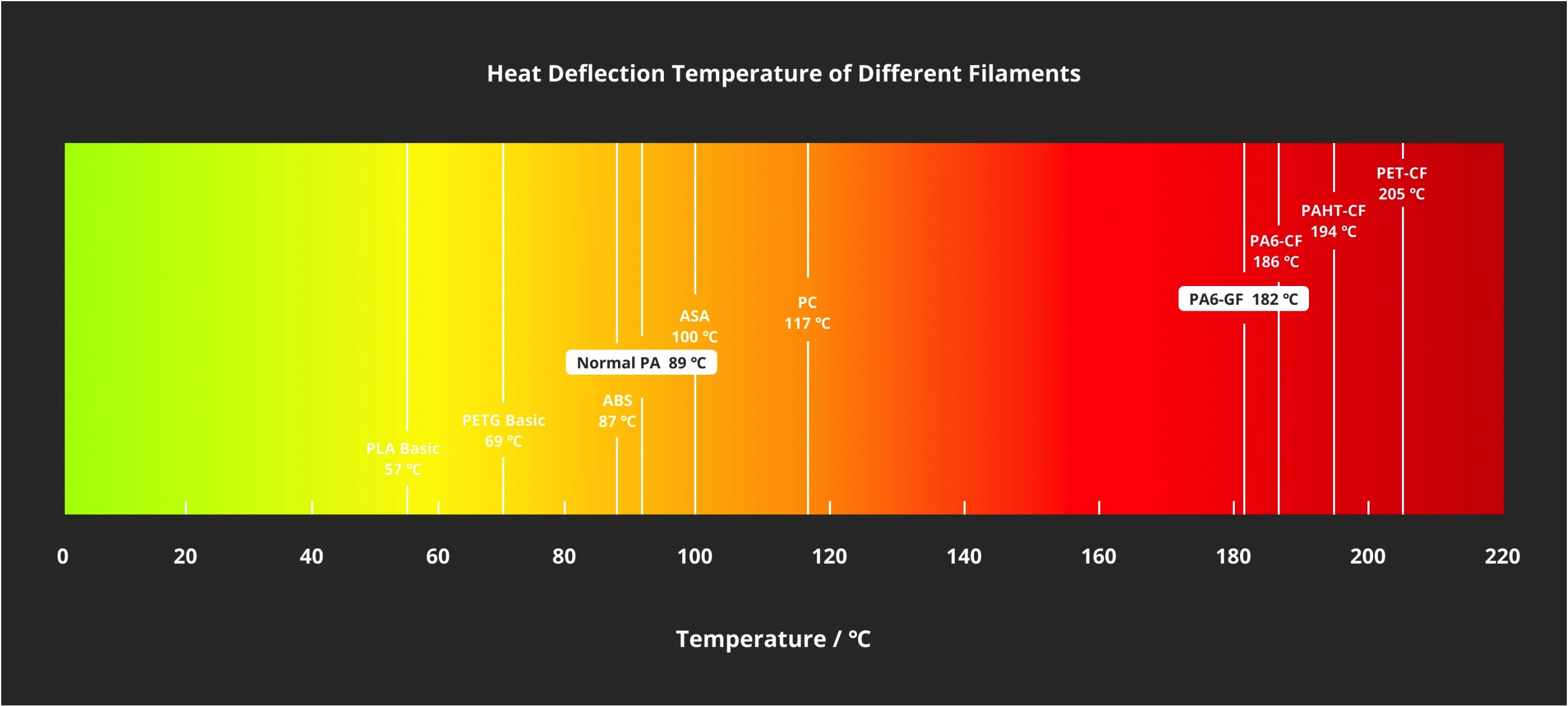

Exceptional Thermal Properties

PA6-GF boasts a high heat deflection temperature and superior dimensional stability, enabling it to retain its mechanical properties even under elevated temperatures. This makes it ideal for demanding industrial and automotive applications.

Chemical Resistance

PA6-GF offers excellent resistance to chemicals, oils, and many kinds of solvents, ensuring long-term performance in challenging environments.

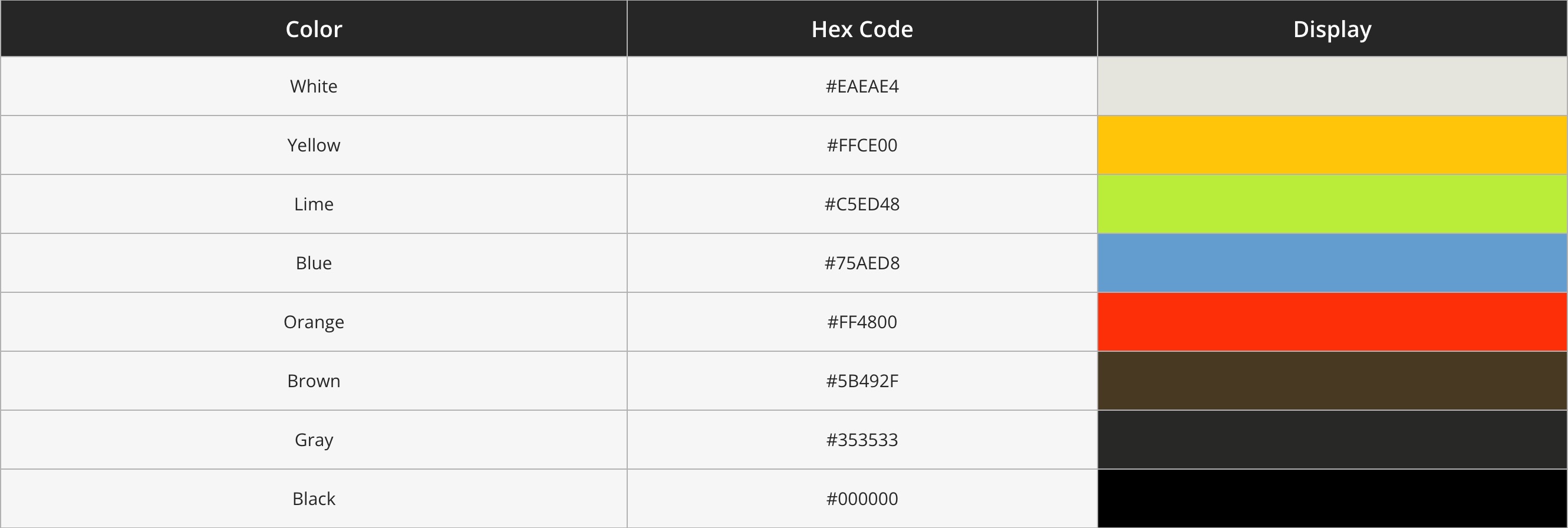

Smooth Surface and More Colors

Bambu PA6-GF filaments are compatible with the Bambu AMS system, ready to print in multi-color. The special surface texture also blurs the layer lines, providing a smooth surface quality.

PA6-GF Hex Code Table

RFID for Intelligent Printing

All printing parameters are embedded in RFID, which can be read through our AMS (Automatic Material System).

Load and print! No more tedious setting steps.

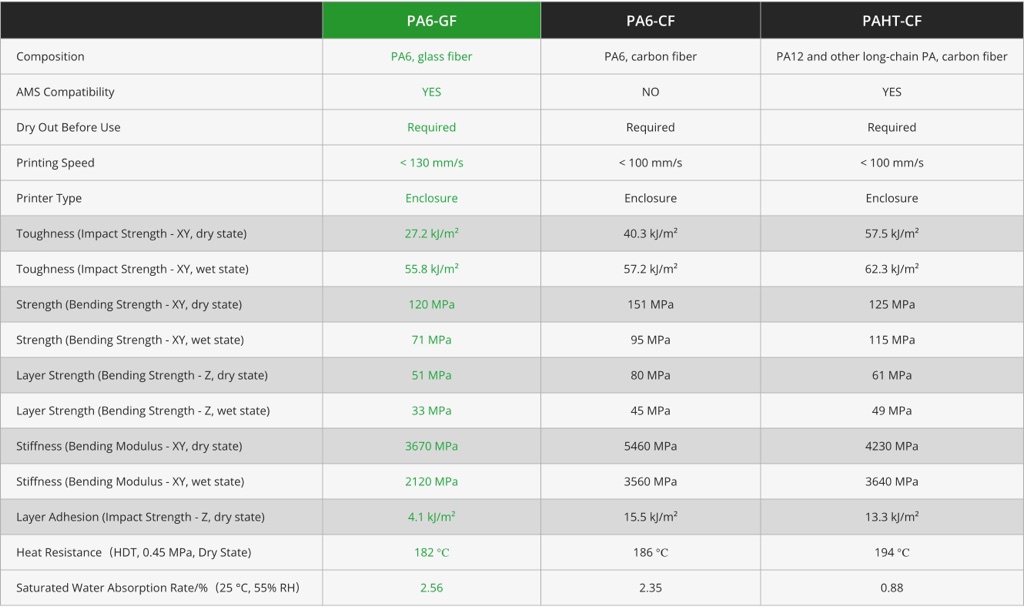

Parameters Comparison

Learn more different filaments comparison on Bambu Filament Guide

Downloads

Filament TDS

Filament TDS

Filament MSDS

Filament MSDS

Filament RoHS

Filament RoHS

Printing Tips

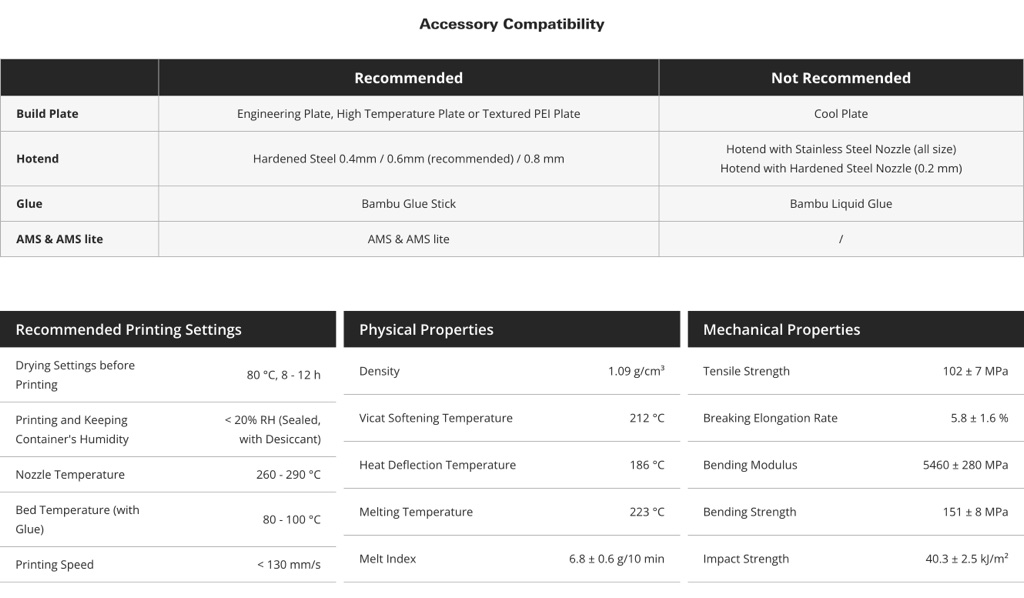

• Bambu PA6-GF needs proper drying before printing: recommended drying temperature is 80 ℃ for 8 to 12 hours in a blast drying oven, or 90 to 100 ℃ for 10 to 12 hours on heat bed. (Do not exceed 100 ℃ because the spool may deform or even melt). For more details, please refer to: Printing tips for Engineering materials on WIKI.

• To prevent the filament from absorbing moisture, it is recommended to use an airtight storage container with desiccant during printing. For more details, please refer to: Printing tips for Engineering materials on WIKI.

• To minimize warping, avoid printing large-sized high infill density models. Use enclosed printers and ensure the build plate is properly applied with glue for better print adhesion before printing.

• For better print results and more details, please refer to: Printing tips for Engineering materials on WIKI.

Post-processing Tips

• We recommend removing the support structures within 2 hours after printing to prevent them from sticking after absorbing moisture. If sticking occurs, dry the model to ease the removal.

• Placing the printed part in a convection oven set between 80 to 130 degrees Celsius for 5 to 12 hours can further enhance the strength and rigidity of the print. Note: The effectiveness of this process depends on the structure, size, and conditions of the printed model. Some models may warp or deform after annealing. For more details, please refer to: Work after Printing Finished on WIKI.

What's in the Box?

Filament with Spool*1 & Desiccant*1

Filament Label*1

Package*1